Mechanical Engineering Calc

27 by Ariyant Creative (0 Reviews) October 03, 2024Latest Version

27

October 03, 2024

Ariyant Creative

Education

Android

0

Free

cal.head.div

Report a Problem

More About Mechanical Engineering Calc

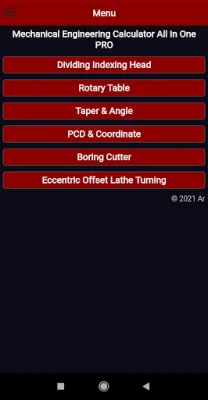

The Tapping Calculator is a versatile tool that offers a variety of useful calculators for machining and engineering tasks. It includes features such as Tap Travel, Press Stroke, Speed, Dividing Indexing Head, Rotary Table, Taper & Angle, PCD & Coordinate, Boring Cutter, Eccentric Offset Lathe Turning, Stepper Motor, Cone to Sheet Development, Turning, Milling, Drilling, Bearing Number Code Name Breakdown, Involute, Inverse of Involute, and Gears Design calculators. These calculators can help users save time and effort by quickly and accurately calculating various measurements and parameters needed for their projects.

The Tap Travel calculator allows users to determine the distance a tap will travel based on the number of turns and the pitch of the thread. The Press Stroke calculator helps users determine the required press stroke for a given material thickness and press force. The Speed calculator allows users to calculate the cutting speed for a given tool diameter and rotational speed. These calculators are useful for tasks such as tapping, pressing, and machining, and can help users optimize their processes for efficiency and accuracy.

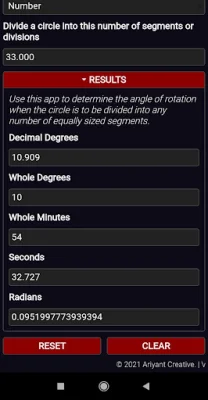

The Dividing Indexing Head and Rotary Table calculators are essential for tasks involving dividing and indexing, such as cutting gears or machining complex shapes. These calculators help users determine the number of divisions or rotations needed for a specific angle or number of teeth. The Taper & Angle calculator is useful for determining the taper angle and included angle for various types of tapers, such as Morse, Jarno, or Brown & Sharpe.

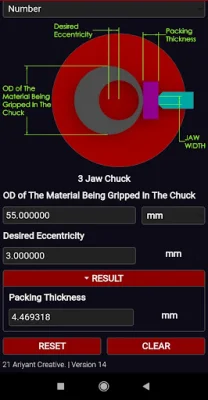

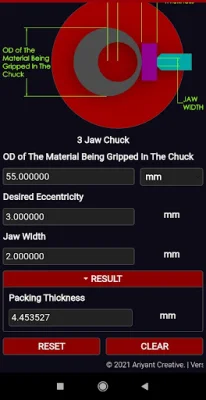

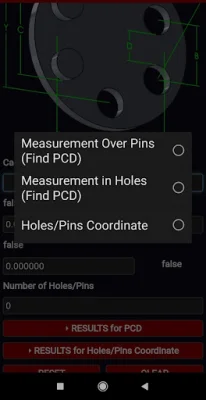

The PCD & Coordinate calculator is a valuable tool for tasks involving circular patterns, such as drilling holes on a bolt circle. It helps users determine the pitch circle diameter and coordinates for a given number of holes and diameter. The Boring Cutter calculator is useful for determining the required cutter diameter for boring operations, while the Eccentric Offset Lathe Turning calculator helps users determine the offset distance for eccentric turning on a lathe.

The Stepper Motor calculator is a comprehensive tool that includes features such as Micro Stepping, Gear Reduction, Leadscrew, Steps/Inch & Resolution, Pulses/Second & Inches/Second & Stepper RPM, Inches/Minute & Inches/Second & Pulses/Second, Stepper RPM & Inches/Minute & Inches/Second, Distance, Steps, Steps/Millimetre & Resolution, Pulses/Second & Millimetres/Second & Stepper RPM, Millimetres/Minute & Millimetres/Second & Pulses/Second, Stepper RPM & Millimetres/Minute & Millimetres/Second, Rotary Table, Steps/Degree & Resolution, Pulses/Second & Degrees/Second & Stepper RPM, Degrees/Minute & Degrees/Second & Pulses/Second, Stepper RPM & Degrees/Minute & Degrees/Second. This calculator is a valuable tool for those working with stepper motors, as it helps determine various parameters such as speed, resolution, and distance.

The Cone to Sheet Development calculator is useful for tasks involving sheet metal development, such as creating cones or pyramids. It helps users determine the flat pattern dimensions for a given cone or pyramid shape. The Turning calculator is a comprehensive tool that includes features such as Cutting Time, Power Requirements, Cutting Speed, Spindle Speed, Feed Rate, Theoretical Surface Roughness, Horsepower, Material Removal Rate, and Cutting Force. This calculator is useful for optimizing turning operations and determining the necessary parameters for a specific material and cutting tool.

The Milling calculator is a versatile tool that includes features for both Metric and Imperial units, as well as Feed Rate Tooth, Table Feed, and Max. Chip thickness (R-insert). It helps users determine the necessary parameters for milling operations, such as feed rate and chip thickness. The Drilling calculator is useful for determining the feed rate per revolution, torque, and thrust for drilling operations. It can help users optimize their drilling processes and ensure accurate and efficient results.

The Bearing Number Code Name Breakdown calculator is a helpful tool for identifying and understanding bearing codes and names. It provides a breakdown of the various components and their meanings, making it easier for users to select the right bearing for their application. The Involute and Inverse of Involute calculators are useful for tasks involving gear design, as they help determine the involute curve and its inverse for a given gear tooth profile.

The Gears Design calculator is a comprehensive tool that includes features such as Module, Working Pressure Angle, Number of Teeth (Pinion & Gear), Center Distance, Outside & Pitch & Base & Root Diameter (Pinion & Gear), Addendum, Dedendum, Speed Ratio, Coefficient of Profile Shift, and Whole Depth. It is a valuable tool for designing and optimizing gear systems, and it includes specific calculators for Spur Gears, Internal Gears,

Rate the App

Popular Apps